CONNECTED magazine n°15

Leading innovation for over 75 years

Few companies can claim to have directly contributed to a technological revolution. The LEMO Group has had the chance to initiate more than one. Among others, it invented the Push-Pull latching system and set the global standard for hybrid fibre optic connectors supporting the move to HDTV. To remain at the forefront of innovation for three quarters of a century requires a lot of passion and commi

LEMO winner of the Best International Company Award in the canton of Vaud

This prize recognizes companies with a significant worldwide presence who are also major contributors to the canton’s economy.The award was presented to Mr Alexandre Pesci, CEO on 23rd November, 2017 by Mr Philippe Leuba, Minister of Economy in front of over 300 attendees.

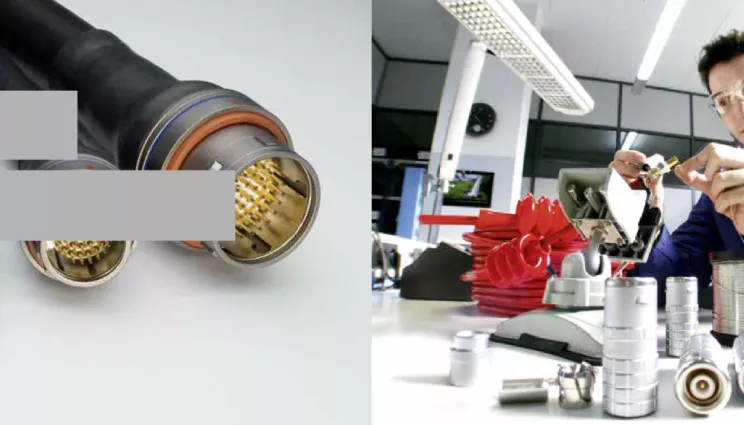

Electronic Connector Counterfeits and Copies

Knock-offs of electronic components, such as connectors, can cause big problems for purchasers, particularly if the purchasers are inaccurately informed as to what they are buying.Indeed, these parts are often deliberately designed to superficially resemble or imitate premium parts that have been manufactured with more stringent design specifications and that offer greater ultimate performance.Thi

Beyond connectors

LEMO’s long experience and solid expertise in the field of connector and cable assembly has now beenextended by offering complete interconnection solutions.

Sculpteo: the success of a factory in the cloud

"There began to be a lot of talk about 3D software,3D objects and 3D printing in 2009” explains Clément Moreau, co-founder of Sculpteo. “For us, it was a new revolution in the history of industry. So we started to get ready for when the big wave would arrive…”

Printing an exact copy of the patient

In the printer are two polymer materials owned by 3D Systems: the material which will “hold” the finest elements and the building material itself. Once it's printing, the machine super- poses – one by one – layers 32 microns deep.