CONNECTED magazine n°4

Leading innovation for over 75 years

Few companies can claim to have directly contributed to a technological revolution. The LEMO Group has had the chance to initiate more than one. Among others, it invented the Push-Pull latching system and set the global standard for hybrid fibre optic connectors supporting the move to HDTV. To remain at the forefront of innovation for three quarters of a century requires a lot of passion and commi

LEMO magazine CONNECTED n°14

The 14th issue of LEMO's CONNECTED magazine is out!Connectors to combat the virusThe urge to breatheAt the heart of the Dakar rally

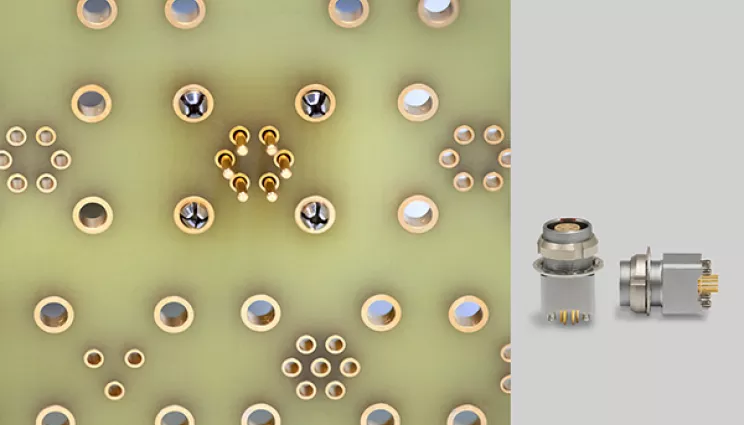

LEMO’s new HARPOON: Press fit contacts for elbow and straight PCB sockets

LEMO connector is well known for its Push-Pull connector. LEMO’s new harpoon earthing pins enable pre-installing easily various receptacles/socket.The advantage of these new press-fit contacts is the gain of time while doing the pre-assembly, no need to place the washers and screw 4 times the M1.6 screws.Simply align the connector and push firmly. This pre-assembly will enable the assembly house o

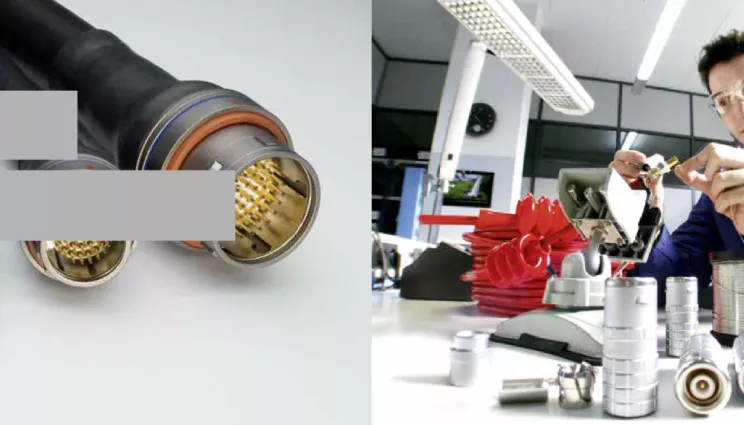

Beyond connectors

LEMO’s long experience and solid expertise in the field of connector and cable assembly has now beenextended by offering complete interconnection solutions.

Sculpteo: the success of a factory in the cloud

"There began to be a lot of talk about 3D software,3D objects and 3D printing in 2009” explains Clément Moreau, co-founder of Sculpteo. “For us, it was a new revolution in the history of industry. So we started to get ready for when the big wave would arrive…”

Printing an exact copy of the patient

In the printer are two polymer materials owned by 3D Systems: the material which will “hold” the finest elements and the building material itself. Once it's printing, the machine super- poses – one by one – layers 32 microns deep.